Choose the Right Rubber Track for Your Machine

When you’re in need of new rubber tracks for your machine, it’s important to choose the right track type to ensure maximum usage and machine uptime. Rubber tracks have a specific purpose, and choosing the right tread that will be compatible with your machine and work application is essential. With so many different options available to choose from, it can be overwhelming to decide which is the best fit for your needs. Here are some key factors to consider:

- Block vs. Bar Tread

- General Duty vs. Heavy Duty

What’s the Difference Between Block and Bar Tread?

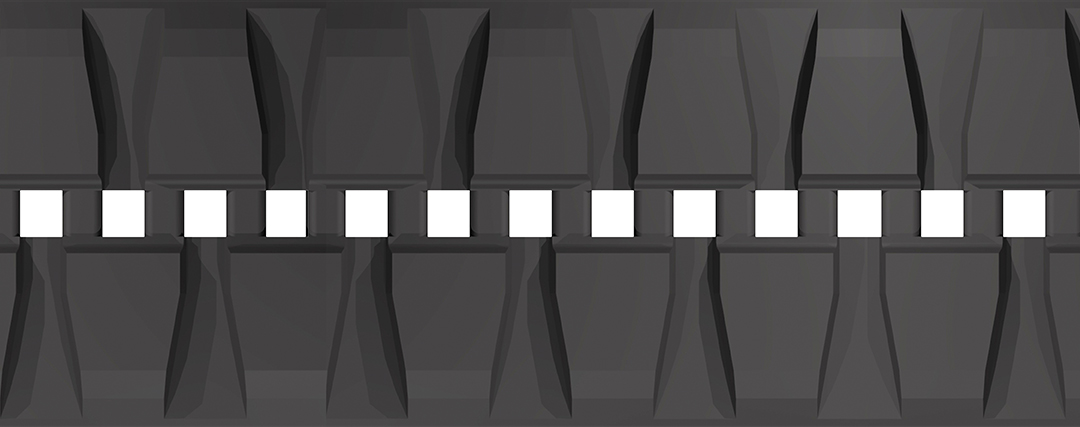

Block Tread

|

|

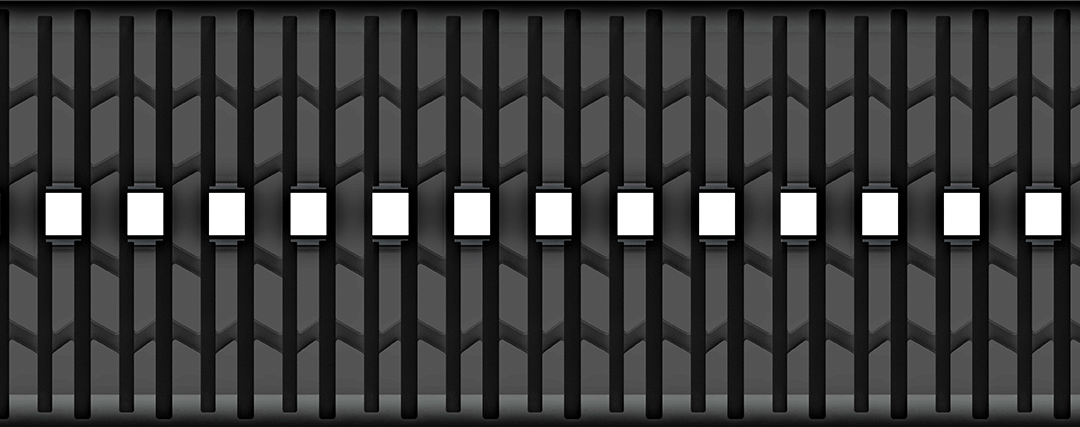

Bar Tread

|

|

What’s the Difference Between General Duty and Heavy Duty Tracks?

The main differences between general duty and heavy duty tracks are expected service life, low or high hour utilization, and pricing.

The general duty rubber tracks are a good option for customers that have lower hour accumulation and are looking to lower their owning and operating costs.

Heavy duty tracks are offered in either narrow or wide track widths and either the bar or block tread patterns. When choosing between the narrow or wide track width, consider the applications in which the machine is most often used. Is low ground pressure with better floatation required? If so, you’ll want to choose a wider track option. If the application demands the narrowest overall machine width, you may want to choose the narrow track option.

Use the Cat® rubber track application guide to find which track type is compatible with your machine and its corresponding part number.

Order today at your local Fabick Cat or online now!